CORE SERVICE OFFERINGS

Infrared Thermography

TCR Arabia in KSA undertakes a thermographic survey of installed thermal insulation on pipework and equipment when in service. The purpose of the inspection/survey is to verify by the measurement of surface temperature that the insulation materials have been applied in a thermally efficient manner, and that the insulation materials are conforming within the ambient conditions, operating conditions and the insulation specifications. Work is undertaken in adherence to the codes specified in BS 5422, the use of thermal insulating materials and in BS 5970, thermal insulation of pipework and equipment (in the temperature range minus 100°C to plus 870°C).

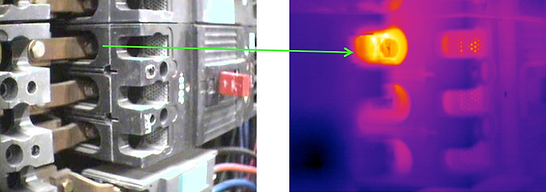

TCR uses thermography tests to find temperature anomalies present in the equipment during their operation. This is based on remote viewing and is a non-contact method of testing. As a recent addition to the NDE, helicopters may be used for testing in large regions. Any hot object that emits heat radiation is captured with an infrared sensor, which picks up the radiation to form the image of the hot body. The hot and cold regions on the surface can be analyzed for the healthy condition of the object. Thermography is useful in applications such as deposits or blockages in pipelines carrying hot or cold fluids, refractory or insulation deterioration in furnaces, boilers, heaters, converters etc. It is also utilized with Electric sub-stations for control panels, transformers, switchgear etc. for overloading, loose or damaged contacts, Overheated bearings in rotary equipment, e.g. motors, generators, turbines, etc.

Equipment

The survey is carried out using fully portable infrared thermal imaging equipment with both “live” and “freeze-frame” recording facilities. All thermography equipment used is from Flir instruments utilizing their latest FUSION functionality which allows for easier identification and interpretation of infrared images. This advanced technology enhances the value of an infrared image by allowing the technician to overlay it directly over the corresponding visible image. The functionality combines the benefits of both the infrared image ad visual picture at the push of a button. The thermography camera of TCR Arabia does this in real-time and the overlay function can be easily adjusted to suit any application such as electrical surveys, building diagnostics, and mechanical inspections.

Inspection Procedure

The assigned technician from TCR Arabia to conduct the survey is fully trained in the operation of the thermal imaging equipment/recording equipment and shall be fully conversant with insulation systems and basic heat transfer physics. The technician will be trained in the analysis of results, identification of anomalies and shall prepare a factual report of findings together with recommendations. The level of the survey conducted and extent of reporting shall be dependent on the client's requirements, objectives, etc. which can be determined prior to the survey commencing.

Preparation

Prior to the site survey, the client shall supply details of areas to be surveyed. Information wherever possible shall include as a minimum:-

a) Line numbers/schedule

b) Equipment numbers/schedule

c) Operating temperatures

d) Applied insulation specifications

Where the survey requirement is only for the location of insulation faults or insulation breakdowns (hot or cold spots as applicable) information required need only be area involved and a general indication of operating temperatures. During survey preparations, TCR Arabia will liaison with the Client site engineer and suitable arrangements and dates for the site survey shall be made.

Documentation and Reporting of Test Results

TCR Arabia's expert inspectors and technicians provide on completion of the site survey, documents all the findings and recordings into the final report. Where applicable images are recorded during the survey, enhanced and printed in the report. The video recording made during the survey forms part of the report. All findings are summarized and the report recommends actions that need to be taken.

APPLICATIONS OF INFRARED THERMOGRAPHY

IR Thermography is a technique that uses an infrared imaging and measurement camera to "see" and "measure" invisible infrared energy being emitted from an object. IR Thermography can help you locate hotspots without contact:

-

Thermography helps in easily determining hot-spots (overheating) especially on electrical systems which can produce catastrophic hazards

-

Qualified team of inspectors to carry out thermography service