CORE SERVICE OFFERINGS

Tube Inspection

TCR Arabia in Saudi Arabia undertakes eddy current, Remote Field Eddy Current, Magnetic Flux Leakage and Internal Rotary Tube Inspection (IRIS) testing of tubular products using internal diameter probe coil (bobbin) for non-ferrous materials and ferrous materials (with magnetic saturation).

Heat exchangers and steam generators used in power plants have several thousands of tubes that must be prevented from leaking. Several test techniques and the related remote field testing methods provide a high-speed inspection to detect corrosion, erosion, cracking and other changes in the tubing.

Eddy Current Testing

Eddy Current Testing (ECT) is a rapid and accurate technique used to detect discontinuities in the tubing, heat exchangers, condensers, steam generators, air coolers, feedwater heaters wires, plates, etc. TCR uses electromagnetic induction to detect flaws in conductive materials. Eddy current testing can detect very small cracks in or near the surface of the material. The surfaces need minimal preparation, and physically complex geometries can be investigated using this method. Eddy current testing is also performed for alloy separation, for the determination of treatment conditions, for making electrical conductivity and for measuring coating thickness. The location of repair welds, girth welds, and seam welds may also be detected on ground-machined surfaces.

TCR has an in-house team of Eddy Current Testing professionals with deep expertise in inspecting a number of tubing in heat exchangers. TCR’s testing devices are portable, contact-less and provide immediate feedback. The eddy current instrument at TCR Arabia is capable of operating at test frequencies upto 8 kHZ with a high speed of 2-Meter Per Second Inspection Speed.

Codes and Standards:

-

Standard for Qualification and Certification of Nondestructive Testing personnel, ANSI/ASNT CP-189

-

ASME Boiler and Pressure Vessel Code Section V Article 8

Pre-requisites: Prior to the testing, all tubes must be cleaned. Cleaning shall be done using hydro jetting with typical cleaning pressures between 280kg/m² and 560 kg/cm² . The adequacy of cleaning must be checked by inserting an appropriate dummy probe / rod.

Equipment: The electronic apparatus used will be capable of energising the test coil with alternating currents of suitable frequencies (for example 1 to 125 kHz) and will be capable of sensing the changes in the electromagnetic response of the coils. The instrument will be balanced with the probe in a defect free position of the calibration tube. The spot will be central on the impedance plane display of screen for differential testing and at one division from the top of the screen for absolute testing.

Evaluation: The expert Eddy Current techinicans of TCR Arabia take the flaw signals generated in tubes under test and then compare it with the signals of the calibration standard.

Remote Field Eddy Current Testing (RFET)

Remote field testing (RFT) is an electromagnetic method of non-destructive testing used by TCR Arabia for the detection and sizing of wall thinning caused by corrosion, erosion, wear, pitting and baffle cuts in ferromagnetic tubes of boilers, feed water heaters, air coolers, and carbon steel heat exchangers.

Remote field eddy current testing (RFET) and near field testing (NFT) are used in combination or individually depending upon the capability of testing machine.

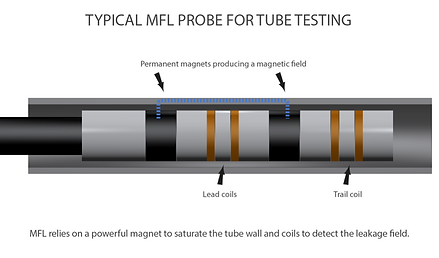

Magnetic Flux Leakage Testing (MFL) for Tube Inspection

Magnetic flux leakage (MFL) is an electromagnetic non-destructive technique that is used by TCR Arabia to detect corrosion and pitting.

MFL uses a powerful magnet to magnetize the conductive material under test (usually steel). Where there are defects — corrosion or material loss — the magnetic field “leaks” from the steel.

-

Inspection technique is suitable for wall-loss detection and measurement of sharp defects, such as pitting, grooving, and circumferential cracks

-

Applicable to ferromagnetic tubing

-

Effective for testing aluminum-finned carbon steel tubes because the magnetic field is mostly unaffected by the fins

-

A good Back-up inspection to Remote Field Testing

Internal Rotary Inspection System (IRIS)

IRIS is an ultrasonic method for the nondestructive inspection of tubes. The IRIS probe is inserted into a tube that is flooded with water, and the probe is pulled out slowly as the data is displayed and recorded. The ultrasonic beam allows detection of metal loss from the inside and outside of the tube wall.

Benefits:

-

IRIS can provide the location of flaw along the length as well as the circumference of the tube

-

Defect detection capability for IRIS is better than RFET (in ferrous materials) but it is inferior to ECT (in non-magnetic materials) as IRIS is not as capable of detecting smaller defects when compared to ECT

Limitations:

-

The major disadvantage is that it is a very slow technique (scanning speed @ 1 inch per second), but accurate in wall measurement of ferrous tubes in range of 0.15mm

-

IRIS inspection requires a better cleaning of surface than eddy current testing

Acoustic Eye Testing

TCR Arabia engages in advanced NDT inspection of heat exchangers and boiler tubes by employing the latest Acoustic Eye tube inspection technology to discerning users for the safety and integrity of their process equipment. Acoustic Eye tube inspection is fast (10 seconds per tube, up to 2000 tubes inspection in one shift of 12 hours), non-invasive and provides inbuilt computerized signal analysis tools to quickly identify tube faults (e.g. pitting / wall loss, erosions, holes / leakage, blockage, bulging) in heat exchangers / condensers / boilers / chillers / reactor tubes.

Acoustic Eye’s breakthrough, non-invasive solution for today’s hard-to-inspect tubes up to 4” inner diameter enables ultra-fast, accurate inspection of boilers, Fin Fans, and other heat exchangers, regardless of the tube shape or the type of material.

Main advantages:

-

It can test up to 4” inner diameter any shape or tube material

-

Ultrafast, non-invasive, inspection in less than 10 seconds, 5 seconds for less than 6m tube – it is ideal for 100% inspections and emergency situation.

-

It can detect blockages apart from pitting or punctures- useful for detecting the extent of cleaning, to increase the efficiency of the heat exchanger

-

Non-Traversing NDT system with no moving parts

-

Fast inspection of tubes- the time taken for each tube irrespective of the length is 10 seconds for inspection

-

Tube wall material can be used for tubes of any material

-

Tube configuration independent (fin tubes, U-tubes, multi bends, 90 deg turns)

-

Extremely accurate results

-

Self Analyzing special software does automatic analysis using Matlab and C++

-

Automatic report Generation (in PDF/HTML format)

-

Can be used for tubes from 7 mm ID to 70 mm ID

User benefits:

-

Fast and accurate detection of tube faults and type, position/ location and size/extent of faults

-

Resultant time-saving in taking corrective actions on tubes with defects

-

Faster turn-around of equipment contributing to faster unit/plant startup

Automated Reformer Tube Inspection System (ARTiS)

TCR Arabia has indigenously developed an automated robotic crawler to aid ultrasonic inspection of reformer tubes. It provides tabular and interactive digital output. The 1st point on every tube is referred at the bottom of the tube, climbing up to 14 meters height and provides tube data at every 0.1-meter distance.

The ARTiS can simultaneously collect tube data such as ultrasonic dB level of attenuation, the diameter of the tube and bowing angle at every location. An interactive, graphical user interface is part of the digital report along with a conventional hardcopy printed in a tabular format. ARTiS can perform all these tests at a time, providing integrated and interactive digital inspection record. ARTiS has leading advantage to inspect from the external surface without needing the removal of catalyst. The system measures creep strain with high precision IR sensors. Mid-wall fissures are detected through ultrasonic flaw detection. Use of gyroscopes measures the precise level of bowing. More than a gigabyte of data is gathered for each tube inspected inclusive of flaw detection dB levels with screen captures, bowing and creep strain. Precision encoders used in crawling ensure accurate location of defectives and generation of 3D plots across the length of the tube.

Few of the key advantages of using ARTiS:

-

The method follows a similar technique of manual ultrasound coupling making it an industry-wide proven technique of inspection

-

A macro-level view of the overall tube condition in the reformer is also reported, emphasizing troublesome areas/corner of the furnace if any

-

The outcome of inspection work becomes more systematic and traceable with point-wise reading on each tube for ultrasound attenuation and creep strain

-

It avoids the need for scaffolding, saves total tube inspection time and helps to achieve a reduction in shutdown time of the plant

-

Automation deploys limited water source for coupling and nearly eliminates the need for overhead water drum arrangement, which overcomes additional issues related to drum filling, vacuum water clogging, etc.

-

No surface cleaning needed

-

Faster – precise PC controlled movement

-

Full coverage across length of the tube

ARTiS allows TCR's inspectors to perform multiple inspections on Reformer Tubes including Fissure detection, Creep Strain measurement, Visual Aid and Bowing Measurement.

Fully Saturated Eddy Current Testing

Saturation Eddy Current is a non-destructive testing technique that is used by TCR Arabia on thin ferromagnetic materials like CS, Duplex or on materials that are only slightly magnetic like Monel Nickel Copper alloys to detect and quantify internal/external Cracks, Local defects as well as overall wall-loss in ferromagnetic tubes of boilers, feed water heaters, air coolers, and carbon steel heat exchangers.